The possibilities they offer

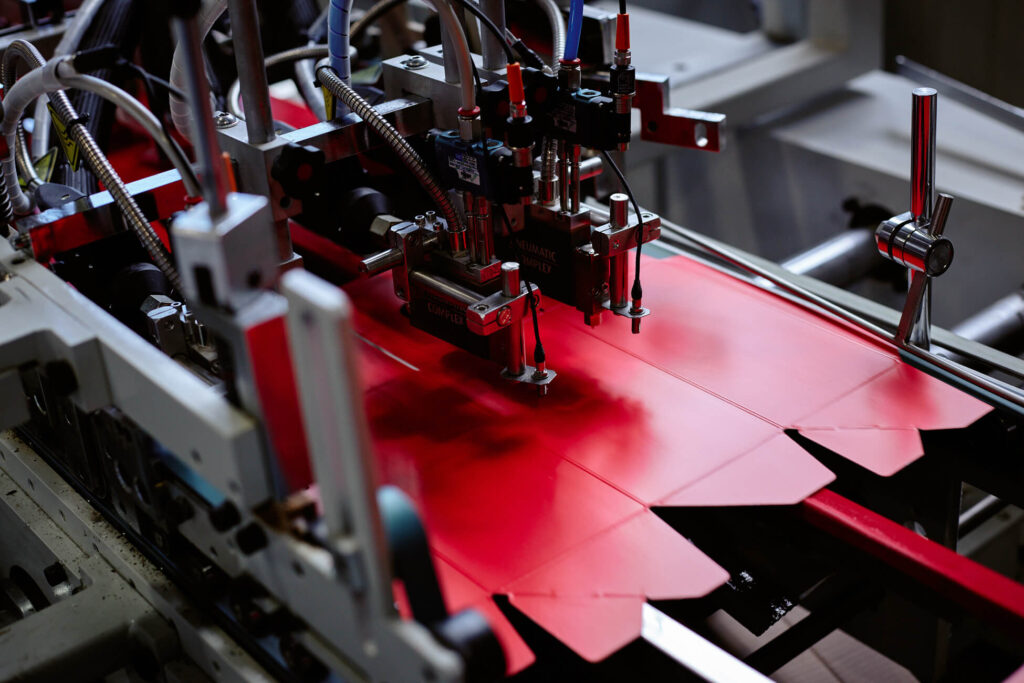

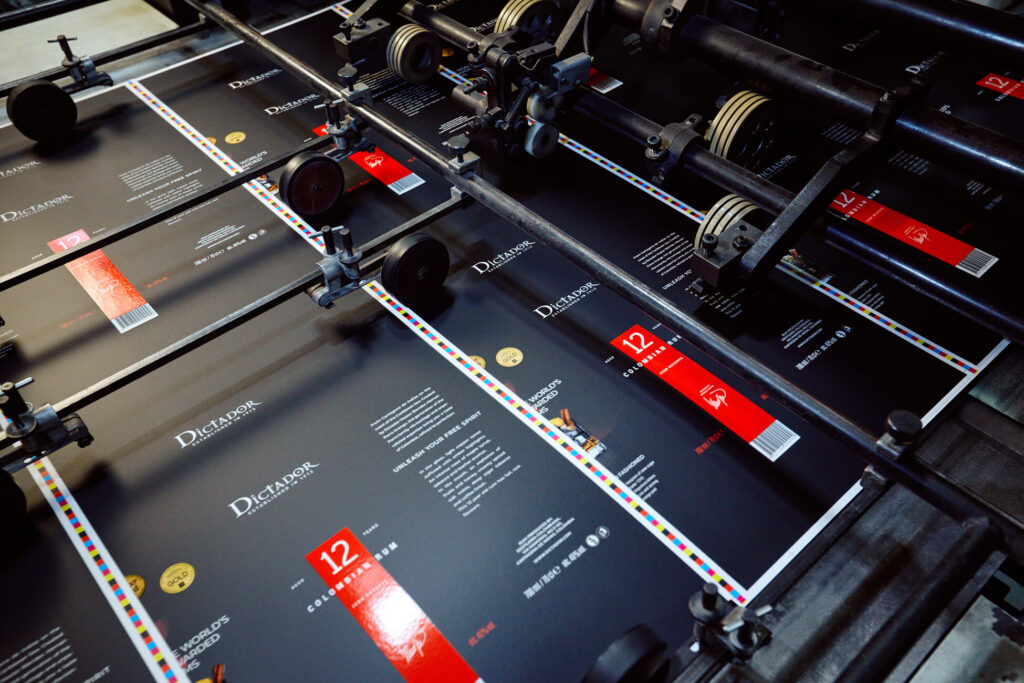

Offset printing

Sheet-fed printing technology is dedicated to producing all kinds of materials from paper, cardboard, foil, PVC.

In conventional technology (paper, cardboard), we have printing equipment in B1 format in 5 colours with in-line varnish.

Printing on non-absorbent substrates (foil, metallics, PVC) is possible using UV/LED technology. Our equipment offers the possibility to print in B2 format in 7 colours with in-line UV varnish including cold stamping.

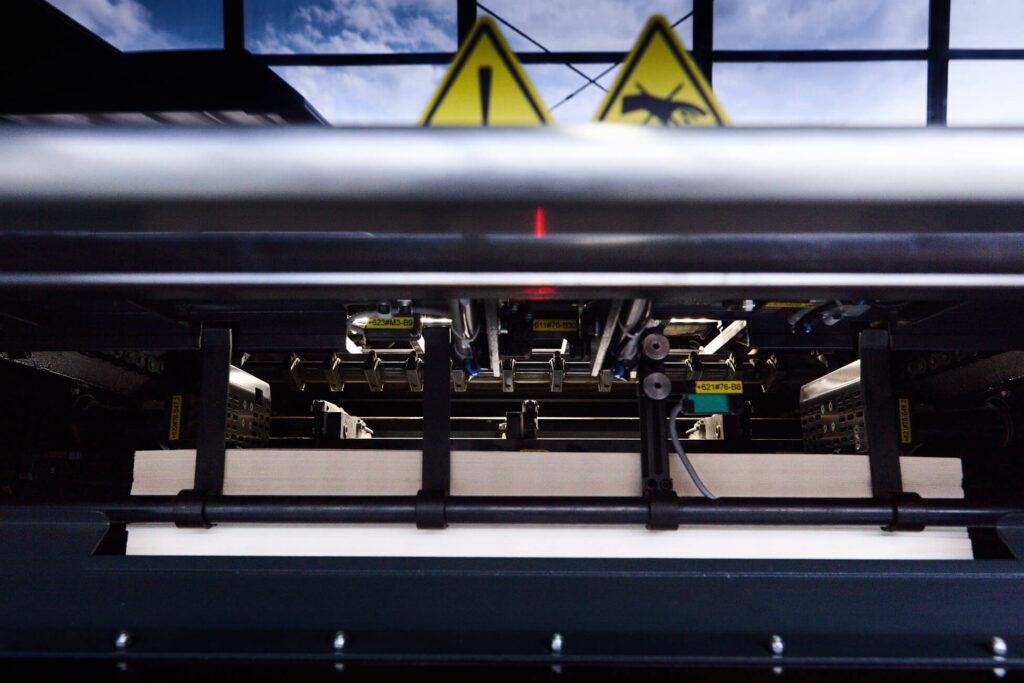

Digital printing

The technology that allows you to print even 1 sheet in the highest quality. The equipment we have today prints on paper, cardboard and film.

We use LED/UV technology printing in 4 colors in B2 format.

As the name suggests, “digital printing” allows us to print short runs of folders, packaging, and also with personalised. We also use it for mock-ups and combined production with offset technology.

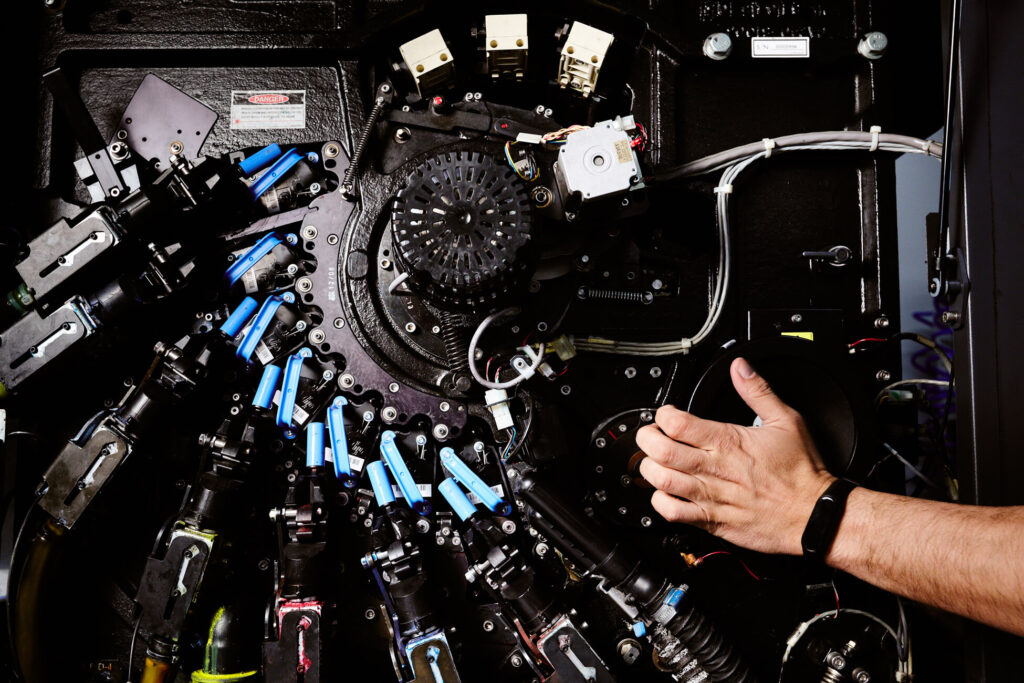

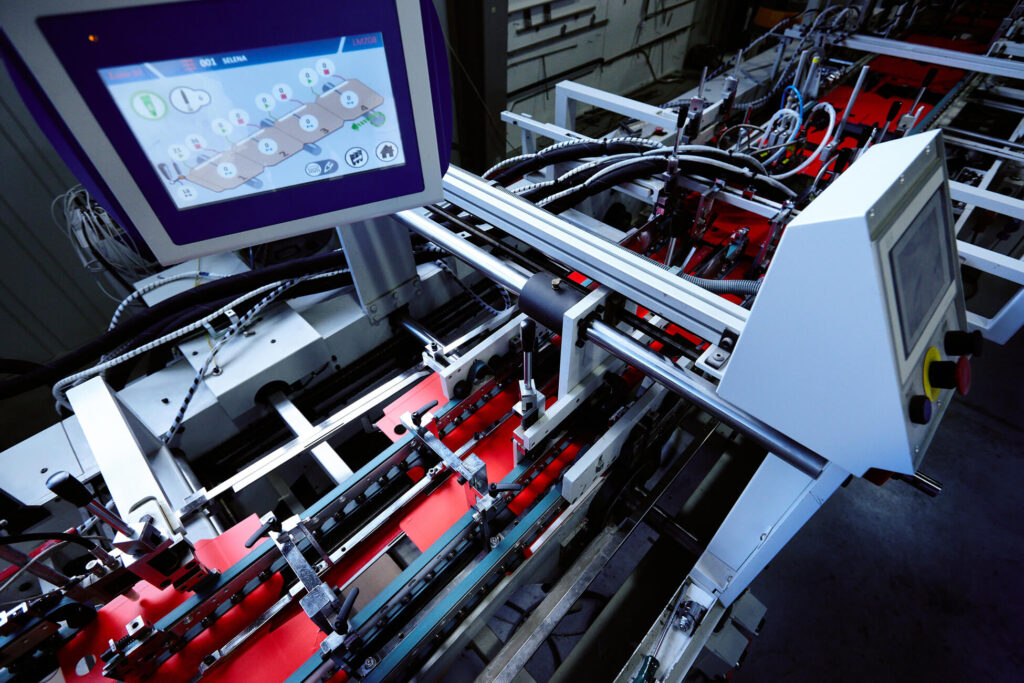

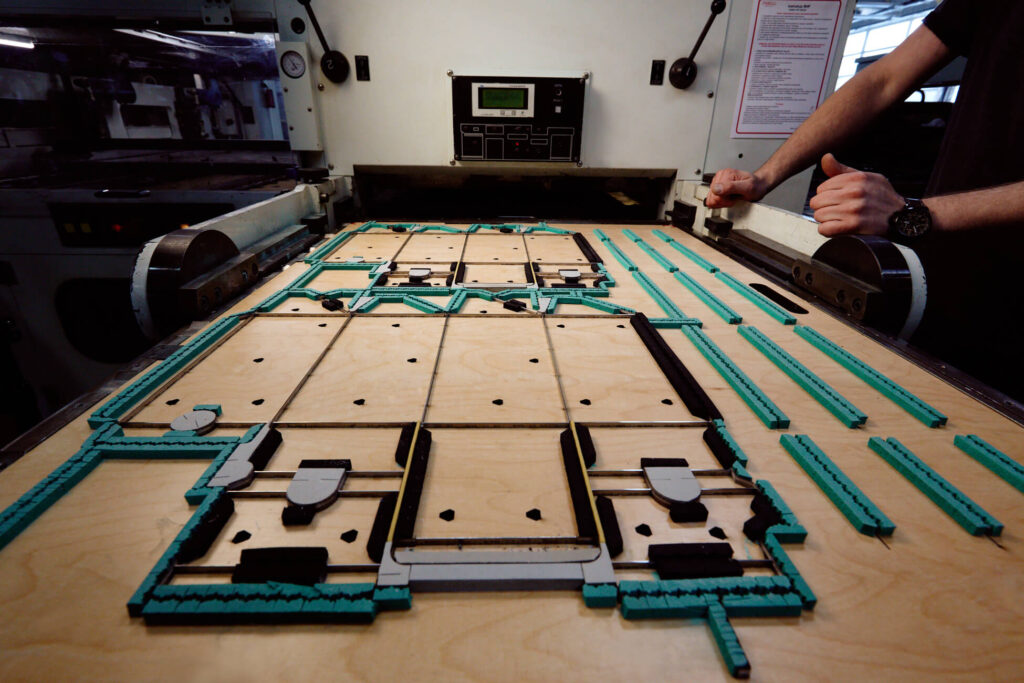

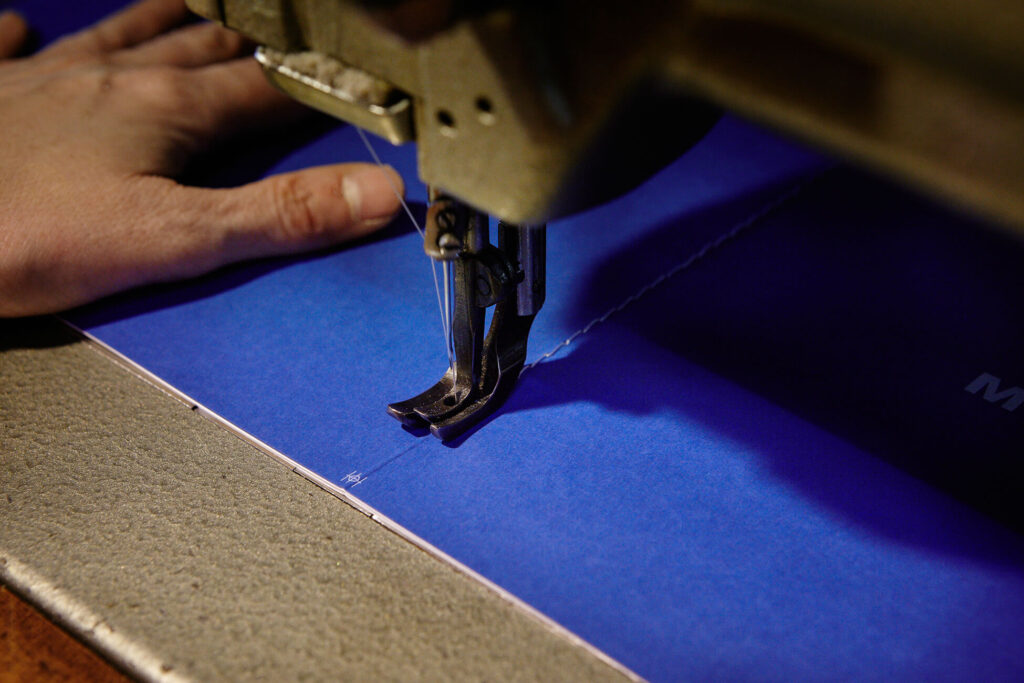

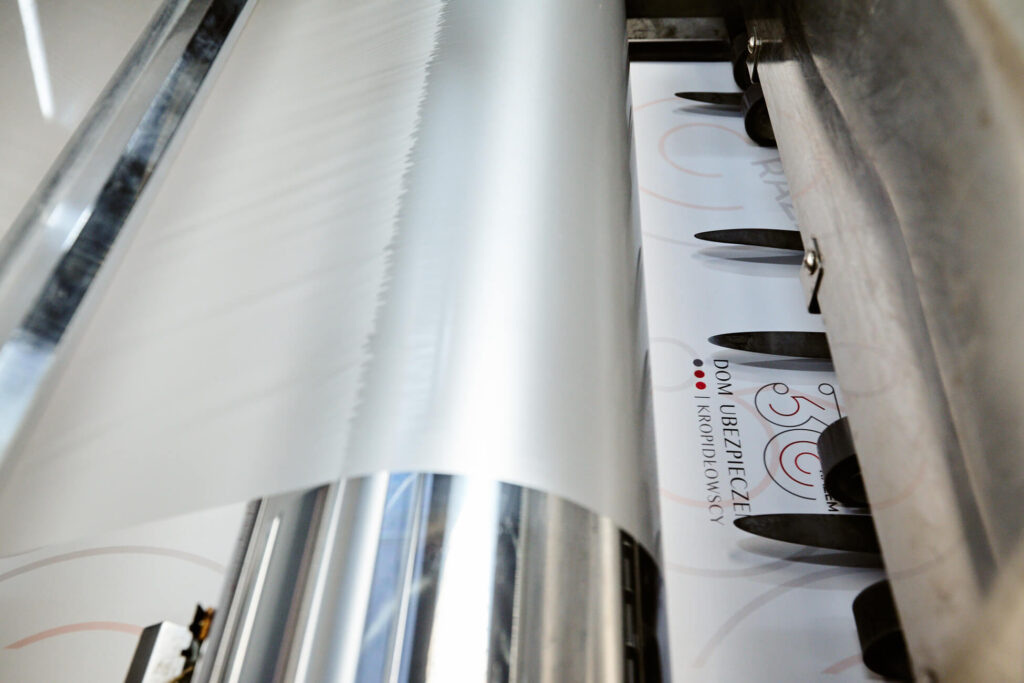

Finishing

Once the sheet is printed, we can carry out a ‘counted’ number of finishing and enhancement operations on your product.

The choice of finish depends on the type and use of your material.

Gilding, embossing, die-cutting, hot stamping, cold stamping, spine colouring, album binding and much more.

B2B portal

We offer our customers the proprietary MellowBusiness platform for designing and managing orders.

It is dedicated to companies with a product portfolio, different branches and many employees who want everything in one place.

The system allows quick editing of projects, generation of reports and expenditure analyses. The possibility of assigning individual permissions allows efficient management of the entire process.

This tool was appreciated by companies such as BNP Paribas Bank Polska S.A., Alior Bank S.A. and Aflofarm Farmacja Polska Sp. z o.o..

Technical issues

If you want to be sure that the finished product will meet your expectations, ensure that the graphic designer is familiar with the principles of preparing materials for printing.

Go to the specifications. We remind you there of the principles that eliminate the differences between your vision and our production. The use of modern printing machinery is 50% of the success. The other 50% lies in the preparation of the graphic design. Try to do it right, but don’t worry too much – we have software that will help you find mistakes. In addition, during the printing process, the Logotronic and Densitronic systems ensure that the printing is stable and that the set colours are reproduced.